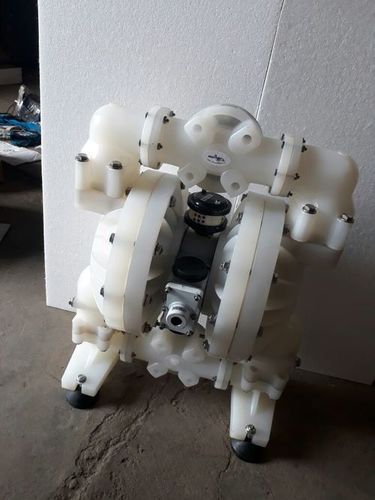

AODD pump

Product Details:

- Material Stainless steel

- Power Electric

- Pressure High Pressure

- Usage Water Oil Well Water Well Automobile Boat Paper Printer Food Air Pump Cosmetics

- Click to view more

AODD pump Price And Quantity

- 1 Unit

- INR

AODD pump Product Specifications

- High Pressure

- Water Oil Well Water Well Automobile Boat Paper Printer Food Air Pump Cosmetics

- Electric

- Stainless steel

AODD pump Trade Information

- 10 Unit Per Day

- 7-30 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Western Europe Middle East Central America Africa South America Australia Asia Eastern Europe North America

- All India

Product Description

AIR OPERATED DOUBLE DIAPHRAGM PUMPS :-

Working Principle :-

The AODD pump is double pumps in one. Chambers A & B are alternatively filled and emptied by drawing liquid in through a common inlet and out through a common outlet (D). The Diaphragms in each chamber are connected by a common shaft so that they move., backwards together. Compressed dry air is directed by the air valve (E) alternatively behind each diaphragm to power discharge strokes. Pump speed and therefore fluid flow-rate can be infinitely controlled by increasing or decreasing or decreasing air pressure and or volume.

Operation Sequence:-

The Blue arrows show the pump cycle. Fluid is being drawn into inlet ( c) by the suction stroke of the diaphragm in chamber B, which opens the ball valve (1) to allow liquid to enter the chamber ,Ball valve (3) is closed by the diaphragm suction.

In chamber (A) air has been applied to the rear of the diaphragm to force out the liquid in the chamber through the Ball Valve (4) to the Liquid outlet (d). This discharge stroke closes Ball valve (2) to prevent further liquid entering the chamber. This cycle is repeated to provide a continuous flow o outlet D.

Standard AODD pumps are one : One ratio-maximum outlet pressure never exceed air supply pressure.

Applications :-

- To Handle Viscous chemicals , Slurries.

- To transfer Explosive liquids , solvents , Acids.

- Pharmaceutical liquids creams and compounds.

- Semi solid foods , flavours , drinks , wine , beer , alchohols.

- Waste water , sewage effluents , coal and lime slurry.

- Hydrocarbons , petrol diesel , lubrication oil , vegetable oil.

- Paints Emulsions , pigments , thinners , resins.

- Ceramics , slip , gazes , clays.

Advantages of AODD Pump :-

- No Seal , No Leakage,

- Self priming , No need of foot valve,

- Variable flow with same pump.

- Can be submerge.

- Less stock of spare to be maintain.

- No Skill person is needed to operation and repair pump.

- Light weight , handy in use.

- No Rotation , no Wear & Tear hence low maintenance , No Charging.

- Pump can run dry.

- Stop Automatic on closing of discharge valve.

- Can handle 2 to 10 mm size solid particles.

- Also can be used upto accuracy 3 to 5%

- No Motor , No fire.

- In short very simple and versatile pump.

Operation Principle :-

- Dry air is given as input to air valve. Air will push both diaphragm alternatively.

- Four ball valves will act as NRV for suction and delivery.

- As per liquid compatibility MOC of diaphragm, Valve and wetted part selected.

Range :-

|

Sr No |

Model |

Material of Casing |

Air Press in Bar |

Max Solid Size in MM |

Suc*Dis BSP |

Flow Range in LPM |

|

1 |

AODD 15 |

PP , SS , PVDF , AL |

7 |

2.5 |

0.5 |

0-25 |

|

2 |

AODD 25 |

PP , SS , AL , PVDF |

7 |

3.4 |

1 |

0-59 |

|

3 |

AODD 40 |

PP , SS , AL |

7 |

5 |

1.5 |

0-137 |

|

4 |

AODD 50 |

PP , SS , AL |

7 |

6.5 |

2 |

0-295 |

|

5 |

AODD 80 |

ALUMINIUM |

7 |

10 |

3 |

0-440 |

The Media AODD pump can handle :-

A full list of chemicals and recommended elastomers is available on request. Or our sales office advice on the best pump & materials for specific media.

Typical range of products you can pump.

ABRASIVES: - Clay slip, Titanium dioxide, frit, Mill scale.

ALCOHOLS ACIDS: - All mineral and organic acids.

CEMENT: - Cement, Mortar.

COSMETICS: - Creams, Emulsions, Detergents.

CAUSTICS

CERAMICS: - Slip glazes, Clay.

DRILLING: - Mud, Grout, Lubricants.

DRINKS: - Soft drinks, spirits, beer, wine, milk.

EXPLOSIVES: - Suspensions of Gun powder explosive, etc.

INKS & DYES: - Printing inks, driers, dyes, sixes and solvents.

FOODS :- Liquid amd semi-solid foods, Flavourings.

OILS :- Petrol , Diesel , Hydraulic and cutting oils , lube oils , animal and vegetables oils and greases.

PULPS :- Paper , wood sizes bleaches

RESINS :- Natural and synthetics , water and solvent based,Monomeric and polymeric plastics.

SLUDGE & WASTE :- Sewage , effluents , coal and lime slurry.

SOLVENTS :- Aromatic and allphatics , ketones , aldehydes, esters and chlorinated hydrocarbons , de-icing fluids.

WATER :- All types.

TIMBER PRESERVATIVES: - Creosote, turpentine, copper, napthenate.

PAINT :- Emulsions , Latexes , Pigments , solvent , resins , thinners,

PHARMACEUTICALS :- Liquids , Creams and Compounds.

PLATING :- Aggressive acids , salts , sludge and effluents.

RUBBER :- Natural and synthetic.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS