Effluent Treatment filter press Polypropylene pump

Product Details:

- Material Stainless steel

- Power Electric

- Pressure High Pressure

- Usage Water Oil Well Automobile Boat Paper Printer Cosmetics Food Air Pump Water Well

- Click to view more

Effluent Treatment filter press Polypropylene pump Price And Quantity

- 1 Unit

Effluent Treatment filter press Polypropylene pump Product Specifications

- High Pressure

- Electric

- Stainless steel

- Water Oil Well Automobile Boat Paper Printer Cosmetics Food Air Pump Water Well

Effluent Treatment filter press Polypropylene pump Trade Information

- Cash on Delivery (COD) Cash Against Delivery (CAD) Cash in Advance (CID) Cheque Cash Advance (CA)

- 10 Unit Per Day

- 7-30 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- All India

Product Description

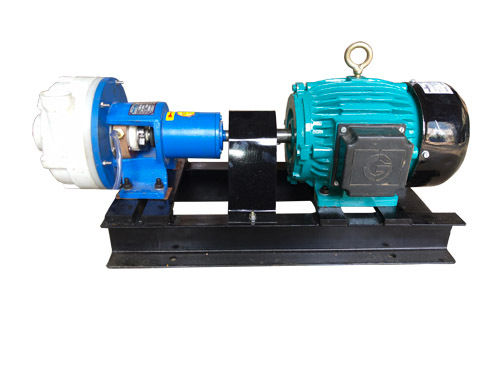

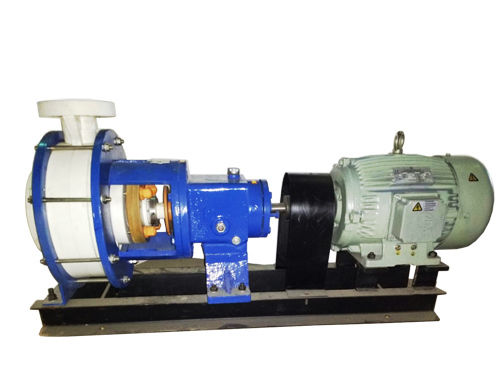

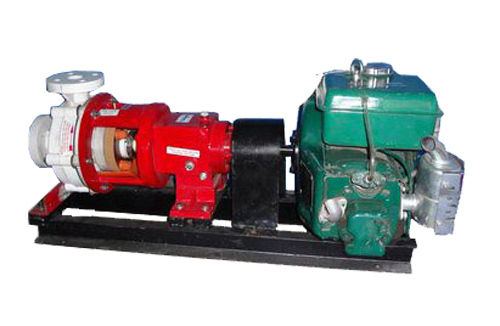

Effluent Treatment filter press poly propylene pump

"MHPP SERIES

APPLICATION

Water treatment Plant

Effluent Treatment

Filter Press for dyes and chemicals

Fertilizer Plants Thermal and atomic power plants

Drugs & Pharmaceutical Industries

Descaling of Tubes

Scrubbing of corrosive gases like C12 , Br , I So2 , NH3 , F2 Etc.

Excellent for vacuum ejectors

Transferring of concentrated HCL from road tankers

Paper & Pulp industries

Pickling in steel rolling mills

Caustic soda plants :- Chlorinated Brine , Conc , HCL , Dilute H2SO4 etc.

PHOSPHORIC Acid Plants :- H3PO4 , H2SO4 , HF and their mixtures with or without solid (gypsum) up to 40% conc.

Gas Washing Plants :- Scrubbed Liquids containing CL2 , BR2 , F2 , I2 , SO2 , SO3 , CO2 , NH3 , Gases etc. with solids replace Hast Alloy.

Rayon Plants :- Spin bath solution (H2SO4 , ZNSO4 , NaSo4 , etc.)

Electro Plating

Pumps are Available in different mounting constructions like Horizontal Bare pump , Monoblock pump and Vertical pump

Pumps are supply with PTFE Gland Packing or Mechanical seal fitted.

Polypropylene parts are manufactured by solid injection molding process.

Mechanical seal are provide of Ceramic / GFT Face or Silicon face with Ptfe bellow as per application.

Gland Packing are used of PTFE Impregnated or PTFE Graphite reinforced as per application Suitable for continuous service.

Pump casing is provide with external metal ring for construction stability.

All non PP parts lined with anti corrosive paint to protect corrosive atmosphere

TEMPERATURE RESISTANCE

PP 50 TO 80 C

PPH 90 TO 100 C

PVDF 100 TO 115C

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS