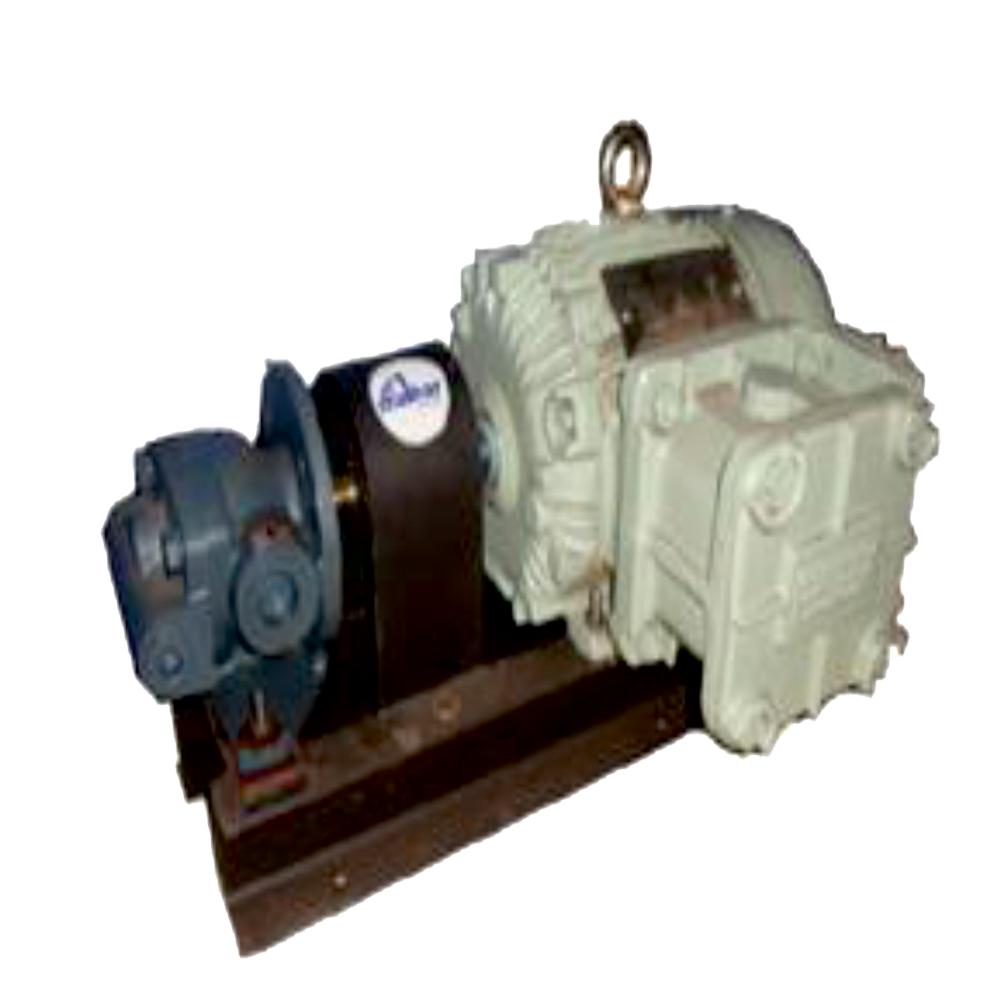

Centrifugal Monoblock Pump

Product Details:

- Theory Centrifugal Pump

- Material Stainless steel

- Power Electric

- Pressure High Pressure

- Usage Water, Oil Well, Water Well, Automobile, Boat, Paper Printer, Cosmetics, Food, Air Pump

- Application Cryogenic, Fire, Maritime, Metering, Sewage, Submersible

- Click to view more

X

Centrifugal Monoblock Pump Price And Quantity

- 1 Unit

Centrifugal Monoblock Pump Product Specifications

- Electric

- High Pressure

- Stainless steel

- Water, Oil Well, Water Well, Automobile, Boat, Paper Printer, Cosmetics, Food, Air Pump

- Cryogenic, Fire, Maritime, Metering, Sewage, Submersible

- Centrifugal Pump

Centrifugal Monoblock Pump Trade Information

- Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 10 Unit Per Day

- 7-30 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Australia, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia, North America

- All India

Product Description

A centrifugal monoblock pump is a type of pump that is widely used in various applications, including domestic, agricultural, industrial, and commercial sectors. It is a single-stage centrifugal pump that is coupled with an electric motor and mounted on a single shaft. The pump and motor are assembled on a common baseplate, which makes it easy to install and maintain.The impeller of the centrifugal monoblock pump is a rotating component that creates a centrifugal force and moves the fluid towards the discharge port of the pump. The fluid enters the pump through the suction port, and the impeller rotates at high speed, pushing the fluid towards the discharge port. The volute casing of the pump converts the kinetic energy of the fluid into pressure energy, and the fluid is discharged through the outlet port.Centrifugal monoblock pumps are known for their high efficiency, low maintenance, and easy installation. They are suitable for handling liquids that are clean, free from solids, and have low viscosity. They are commonly used in applications such as water supply, irrigation, circulation, and transfer of liquids in various industries.Frequently Asked Questions: 1. What is the working principle of a centrifugal monoblock pump?Ans: A centrifugal monoblock pump works on the principle of centrifugal force. The impeller of the pump rotates at high speed, creating a centrifugal force that moves the fluid towards the discharge port of the pump.2. What are the applications of a centrifugal monoblock pump?Ans: Centrifugal monoblock pumps are used in various applications, including water supply, irrigation, circulation, and transfer of liquids in various industries such as food processing, chemical, pharmaceuticals, and more.3. What are the advantages of a centrifugal monoblock pump?Ans: Centrifugal monoblock pumps have several advantages, including high efficiency, low maintenance, easy installation, compact size, and low cost.4. What are the limitations of a centrifugal monoblock pump?Ans: Centrifugal monoblock pumps are not suitable for handling liquids that are viscous or contain solids. They also cannot handle fluids that are corrosive or abrasive.5. What factors should be considered while selecting a centrifugal monoblock pump?Ans: The factors that should be considered while selecting a centrifugal monoblock pump include the type of fluid to be handled, the flow rate, the head pressure, the motor power, the operating temperature, and the installation location.6. How to maintain a centrifugal monoblock pump?Ans: Maintenance of a centrifugal monoblock pump includes regular inspection, cleaning, and lubrication of the pump components. It is important to follow the manufacturers recommended maintenance schedule to ensure optimal performance and long service life of the pump.FAQs of Centrifugal Monoblock Pump:

Q: What is the primary usage of the Centrifugal Monoblock Pump?

A: The Centrifugal Monoblock Pump is primarily used in applications such as water, automobile, paper printing, oil wells, cosmetics, water wells, boats, food processing, air pumping, and many other industries.Q: What is the pressure rating of the Centrifugal Monoblock Pump?

A: The Centrifugal Monoblock Pump is designed to operate under high pressure conditions.Q: What material is the Centrifugal Monoblock Pump made of?

A: The pump is made of stainless steel, ensuring durability and resistance to corrosion.Q: What are the applications of the Centrifugal Monoblock Pump?

A: The pump is suitable for applications such as submersible operations, fire handling, sewage management, cryogenic processing, maritime usage, metering, and more.Q: What is the theory behind the operation of the Centrifugal Monoblock Pump?

A: It operates based on the centrifugal pump theory, which involves converting rotational energy to kinetic energy to move fluids effectively.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS