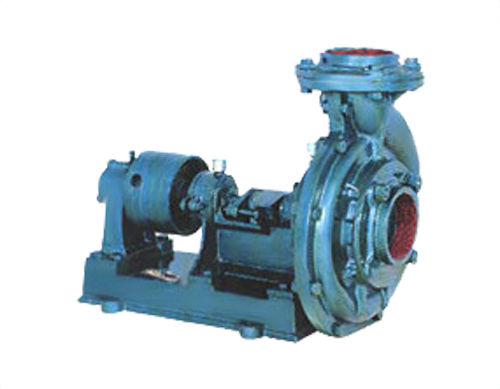

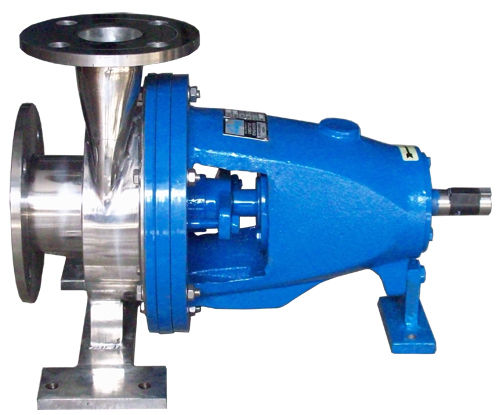

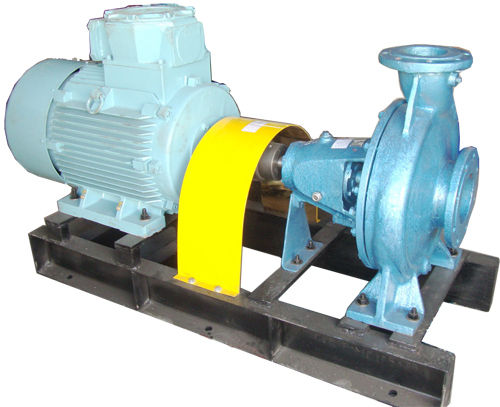

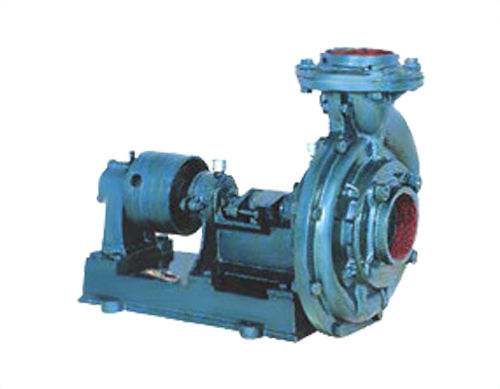

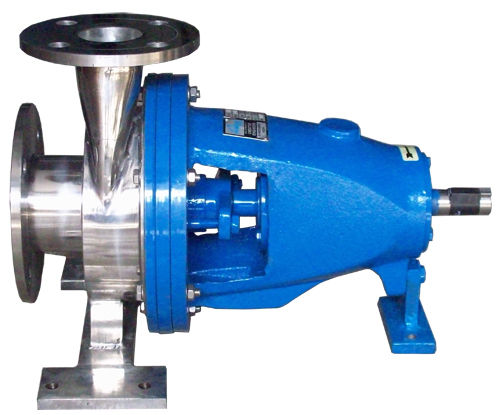

SS Chemical pump

Product Details:

- Material Stainless steel

- Power Electric

- Pressure High Pressure

- Click to view more

X

SS Chemical pump Price And Quantity

- 1 Unit

- INR

SS Chemical pump Product Specifications

- Electric

- Stainless steel

- High Pressure

SS Chemical pump Trade Information

- 10 Unit Per Day

- 7-30 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- All India

Product Description

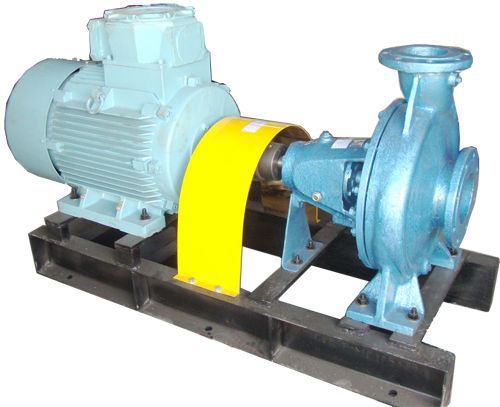

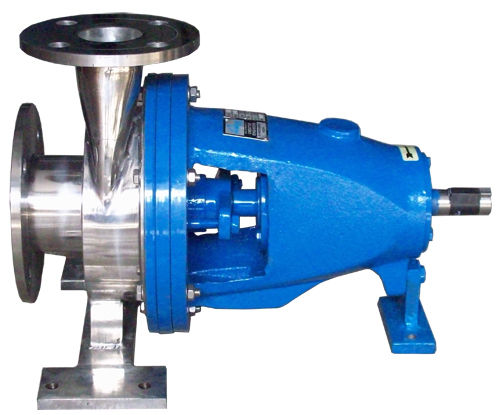

SS Chemical pump Back Pullout Pumps "BPO"

Features :

For pumping clear/turbid water/chemicals & volatile liquids.

Air conditional plants, power station, mine drainage, sprinkler systems fire fighting, booster service, oils, brine.

Delivery sizes up to 250mm

Capacity up to 990 m3/hr

Head up to 120 meters

RPM 500 to 3600

Features :

- More than 3mm corrosion allowance (cast iron) for extended use on corrosive applications.

- Back-pull-out construction allows rotating assembly to be with drawn without disturbing the suction and delivery connections.

- one piece self vanted foot mounted, center suction volute casting, single stage, closed / semi open dynamically balanced impeller.

- Flange drilling standards as per DIN 24255 / ISO 2858 or as per customer's requirement.

- Designed for 16 bar working pressure with optional casing for a working pressure of up to 20 bar.

- A robust and solid construction that guarantees long life even under high suction pressure conditions.

- Heavy-duty, deep-grooved bearings with minimum 50,000 hours operating life under normal condition. (Grease lubricated, oil lubrication available on request)

- Heavy-duty, stiff solid shaft design with low L3/D4 ratio ensures less than 0.05mm shaft deflection at the seal face in all operating condition. This extends the seal life.

- Seal housing is constructed to accommodate different seal/gland designs, so as to meet the severe heavy-duty requirements.

- Excellent parts interchangeability reduces inventory levels for spare parts to a minimum.

- Special design for high temperature thermic fluid available in request.

- Motor or Engine driven set

- Special Monoblock versions available on request

For pumping clear/turbid water/chemicals & volatile liquids.

Air conditional plants, power station, mine drainage, sprinkler systems fire fighting, booster service, oils, brine.

Delivery sizes up to 250mm

Capacity up to 990 m3/hr

Head up to 120 meters

RPM 500 to 3600

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS